Portsmouth technician puts 3D printer to work in aid of NHS staff members

and live on Freeview channel 276

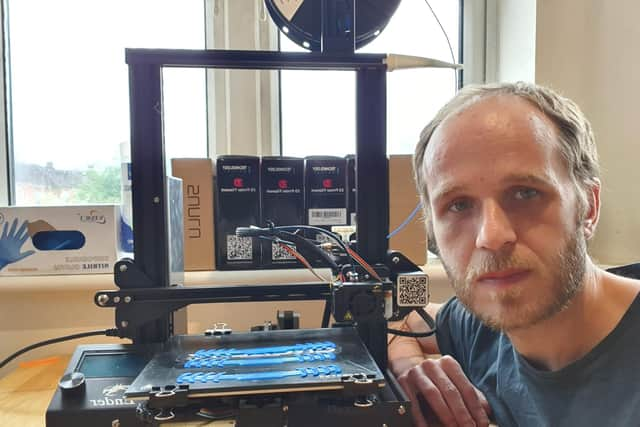

David Collins, who works for technology solutions firm Dunstan Thomas, is using his time to create ear savers on his 3D printer.

These ear savers attach to the protective face masks being worn in hospitals, reducing the strain around the ears and skin.

Advertisement

Hide AdAdvertisement

Hide AdThis means staff are less likely to suffer skin damage from wearing a mask throughout their shift.

David said: ‘It started when a friend of mine got in touch and mentioned that they were running low on these ear savers.

‘He knew I had a 3D printer and asked if I could help; it was something I could easily do, so I began printing them out, and more and more people needed them so I kept printing them out.’

So far David has printed more than 160 ear savers for the NHS.

Advertisement

Hide AdAdvertisement

Hide AdAs demand for them increases, so will his workload – but David will not see any commercial gain for his efforts.

He said: ‘Although it’s not a frontline medical device, these ear savers make wearing masks easier and generally more comfortable for doctors, nurses and other clinicians.’

The ear savers are made from a material called PLA, which is plastic made from a base of renewable materials, such as corn and starch.

The tool is printed out using a FDM 3D printer, which has been customised with a glass bed and updated firmware.

Advertisement

Hide AdAdvertisement

Hide AdThis means it takes around 75 minutes to print a batch of seven ear savers.

David says he’s tried a number of designs, settling on the current design due to its flexibility.

Once completed, the ear savers are vacuum packed and sent out in envelopes to NHS institutions across the Portsmouth region.

The use of 3D printers to create personal protective equipment (PPE) by regular Portsmouth workers has proved to be a crucial asset in the city’s fight against the Covid-19 outbreak.

Advertisement

Hide AdAdvertisement

Hide AdPPE includes the face masks, gloves and eye protection – designed to protect the worker and prevent the spread of the virus.

A message from the Editor

Thank you for reading this story on portsmouth.co.uk. While I have your attention, I also have an important request to make of you.

With the coronavirus lockdown having a major impact on many of our advertisers - and consequently the revenue we receive - we are more reliant than ever on you taking out a digital subscription.

Subscribe to portsmouth.co.uk and enjoy unlimited access to local news and information online and on our app. With a digital subscription, you can read more than 5 articles, see fewer ads, enjoy faster load times, and get access to exclusive newsletters and content. Visit our Subscription page now to sign up.

Our journalism costs money and we rely on advertising, print and digital revenues to help to support them. By supporting us, we are able to support you in providing trusted, fact-checked content for this website.

Comment Guidelines

National World encourages reader discussion on our stories. User feedback, insights and back-and-forth exchanges add a rich layer of context to reporting. Please review our Community Guidelines before commenting.