Two firms - BAE Systems in Portsmouth and Formaplex in Havant - come together to help create specialist equipment for Team GB's Nordic Ski Team ahead of the Beijing Paralympic Winter Games 2022

and live on Freeview channel 276

BAE Systems in Portsmouth and Formaplex in Havant donated time, skills and expertise in order to engineer equipment for the county’s Nordic ski team.

The firms unveiled their work with 100 days to go until the opening ceremony in Beijing.

Advertisement

Hide AdAdvertisement

Hide AdThe two firms teamed up with Williams Advanced Engineering and GB Snowsports to develop ‘Sit-Skis’ to be used by the four-man Para Nordic World Cup squad – Steve Arnold, Callum Deboys, Scott Meenagh, and Steve Thomas.

Defence firm BAE Systems and advanced composite manufacturer Formaplex worked on the design and manufacture of four bespoke ‘Sit-Skis’, including using specialist technology to make the seats bespoke to each of four Paralympians accommodating for their different disabilities.

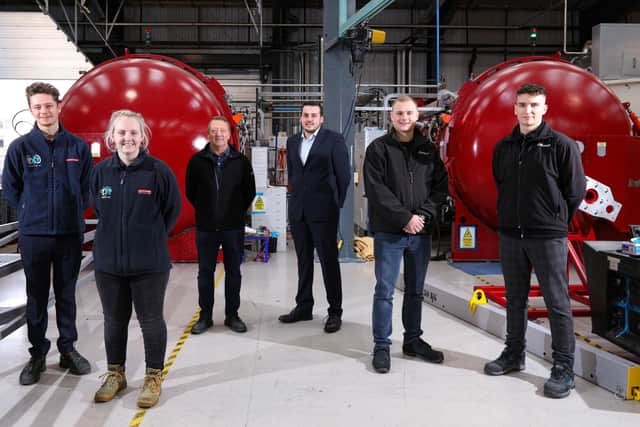

Apprentices Thomas Robinson and Ellie Hamilton from BAE Systems worked on the project overseen by team leader Richard Swain.

Richard said: ‘This was a great opportunity to use our advanced design and manufacturing technologies to help Britain’s Paralympic athletes prepare for the winter Olympics. We have a well-established partnership with Williams Advanced Engineering and to work alongside them and GB Snowsports on a project like this was a real pleasure.

Advertisement

Hide AdAdvertisement

Hide Ad‘It gave our apprentices a great experience of using their skills on new materials and to solve new problems, which helps develop their problem solving abilities. We are fortunate to have such good suppliers such as Formaplex, local to our base in Portsmouth, who could provide vital manufacturing and design capability.

‘It’s great to see the project through from design phase into manufacturing, testing, tailoring and adjusting the Sit-Skis for each athlete. We wish these athletes the very best of British luck.’

BAE Systems worked closely with Formaplex, using their tooling to manufacture the tailored seats, which are bespoke to each athlete’s individual requirements, and a common ‘fin’, which attaches the seat to the skis.

Ryan Fox, project lead at Formaplex, said they were proud to have contributed.

SEE ALSO: Fareham firm Matrix IT appoints three new directors and five new technicians as it continues to grow

Advertisement

Hide AdAdvertisement

Hide AdHe said: ‘We took the designs that Williams came up with and with the help of BAE Systems we produced the parts, the seats and the fin.

‘Formaplex started in the F1 industry but we have gone from that to automotive production using lightweight materials such as carbon fibre to make our components and that technology translates directly into this.

‘Hopefully the lightweight parts that we have created for the Paralympics will help the team bring back a gold medal.’

The Sit-Skis, which are now with Team GB in Canada while they get ready for the Games, are designed to be lightweight but deliver high performance in terms of their strength and geometry, providing a highly controllable and fast ski platform for athletes. The design is also modular, making it easier to create multiple units and maintain consistency for testing.

The design and materials also benefitted from input of experts from Coventry University.

Comment Guidelines

National World encourages reader discussion on our stories. User feedback, insights and back-and-forth exchanges add a rich layer of context to reporting. Please review our Community Guidelines before commenting.